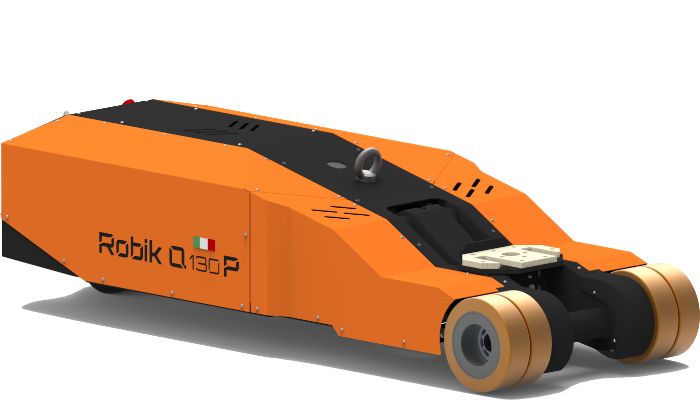

Electric tow

Electric lift- Towing capacity > 20 tons

With lifting plate

Radio controlled guide

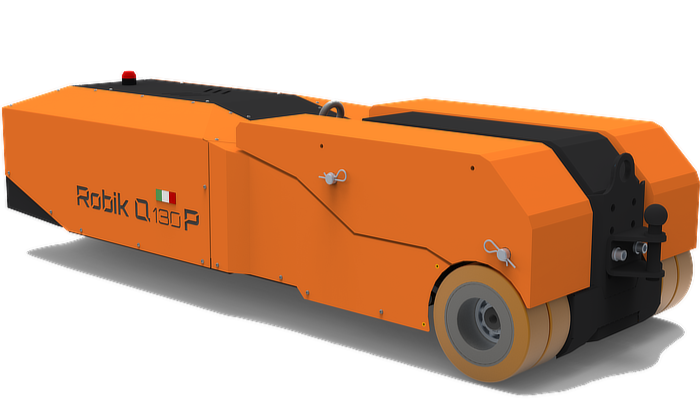

Electric tow

Electric lift- Towing capacity > 20 tons

With ballast

Radio controlled guide

Electric tow

Electric lift- Towing capacity from 5 to 20 tons

With lifting plate

Radio controlled guide

Electric tow

Electric lift- Towing capacity from 5 to 20 tons

With lifting plate

Steering with rudder

Electric tow

Electric platform- Towing capacity up to 10 tons

Radio controlled guide

Wheels

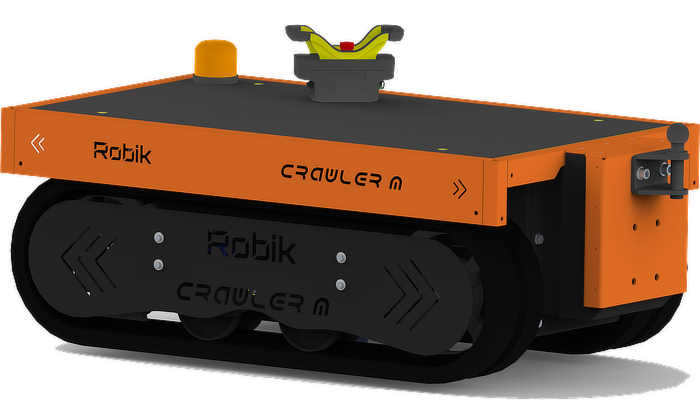

Electric crawler

Electric tow

Electric platform- Towing capacity up to 10 tons

Radio controlled guide

Tracks

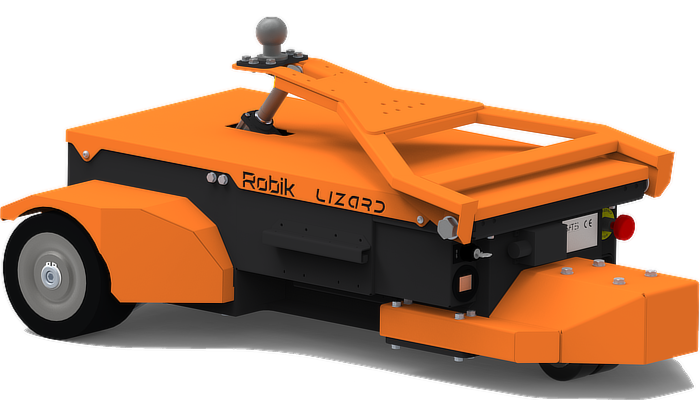

Electric tow

Electric platform- Towing capacity up to 5 tons

Radio controlled guide

Wheels

Electric crawler

Electric tow

Electric platform- Towing capacity up to 5 tons

Radio controlled guide

Tracks